Afternoon Laser Everything Crew!!!

From what I can find: Gantry lasers make the big bucks, while fiber

lasers make the fast bucks. If you get an 80ish-watt gantry and a

20-50-watt fiber, you should be able to do most jobs.

Assumptions:

– Assuming I need residual capital, but bootstrapped and prefer to try and use as little of it as possible.

– This is also a side hustle to make extra money to hopefully become a business. I have been planning a way to start for a while now.

The Limits: My uncle has offered me a 10k no-interest family loan, no

monthly obligation either. After expenses, I send the profit to him.

I can either get:

– 60w MOPA with residual working capital (4k Leftover)

– 55w Polar+ & 20w MOPA with (4k Leftover)

– 60w Maker 20” x 28” & 20w MOPA

I have limited space. The first two options let me start this from my

office space. The third, I would have to rework the limited space in

my dungeon of a basement. My preference would be to go 60w MOPA. I wish to focus on metals and quick items. I have a kid, a job, and other usual domestic items, so I need to squeeze in the work. I have a lot of connections for what would be small items to be produced in my area.

I have experience using and producing simple items on a Monport Hobby K40 with LightBurn.

Sincerely, Undecided in New Jersey

Hey Undecided!

I like the organization and thought you've gone through—and I mostly agree with your findings. Each wavelength has something they do exceedingly well (more so than other wavelengths). Fiber does your metal marking and engraving, CO2 gantry does your organics, wood cutting and engraving, etc. UV is honestly where the bar is set for glass these days, it's just not even a competition with CO2 anymore. Diode is similar to CO2 for functionality, but it's got a smaller dot size and is really ideal for marking rather than cutting—and has some other functional curveballs that give it overlap with other wavelengths for specific projects.

I don't like “poo-pooing” specific lasers when someone has an idea of what fits for their needs, but I just want to share some opinions that make some options not awesome for my preferences, and might affect how you enjoy (or don't) your unit after you get it. The absolute last thing I want is for you to get a machine and find it infuriating to operate. I figure at least if I give you our train of thought behind how we would go about it, it gives you some points to balance against your needs and help decide which is better for you.

The loan situation sounds like you have an awesome opportunity, and there's a lot of options thankfully that get you near or in the ballpark of two different machines, which means more material/project potential so you don't have to turn away certain jobs.

The OMTech Polar

It's a nice-looking little machine, and it's compact. The issue I have with it is that it's super limiting on Z-axis travel, so height-wise, you're going to be limited. There is a pass through at the base from what I recall, but I think it's only a small portion that's meant for resting their included rotary down there so there's enough room to fit a cup. Real big cups are going to be a no-go because of the Z depth unless you figure out some kind of drop table system where you can have no table under the cutout in order to control the height at will more easily. As long as it does what you need, that's what's important. It just drives me nuts personally because now if I want to do a large object or cup, my laser is no longer self-contained, I could burn the table it's sitting on if the job freezes, airflow and fume control, etc. It's not a huge deal if you know that's gonna fit your needs and can work around the concerns, but if it doesn't, then at least you know it's not for you before dropping the 3–4k.

The method their head uses to move the entire assembly of the head for focus is absolutely infuriating too. If you want to rerun a job for batches of items, you have to redo the focus process—it doesn't just stay at a height, it pulls the head up as part of the re-homing process at the end of each job or when a job is stopped. For some people, this is a super frustrating thing that can mess up workflow pretty bad, especially if you're doing batch work or want to stop and restart a job. If you forget to refocus, you may nuke a project by accident.

They, at the very least to their credit, do cover the material thickness and tray-less functional area in their spec portion of the product page. Some brands literally go out of their way to omit that info so the machine capabilities get glazed over, good on them for being upfront I guess. They have the listed max material thickness at 0.7 inch to 2 inch without bed, so basically if whatever you want to engrave doesn't fit in that bottom panel that drops out, you're gonna be stuck. Basically only gonna be able to do small cups, thin material cut-outs, coasters or hot plates. This may be fine for your projects, or it may be too limiting.

The other thing is on the original Polar they only had a push button and NO controller screen. On the Polar+ I think they have a touchscreen controller? I'm not super well-versed on it to be honest, but the original absolutely drove me bonkers. You had no method of identifying why something wouldn't run or the error that was being thrown—just a red blinking light when the job wouldn't start—and there was no pattern or anything to identify why. My understanding is this is no longer an issue, but I would just verify before you buy. After experiencing just trying to help people with that on the initial launch, I personally wouldn't spend money on something that has a DSP controller but you get none of the features because they opted to just not install a screen. Would drive me absolutely nuts to use it.

My Suggestion

I would 1000% go with the OMTech Maker 60W. 60W is a solid starter, 80W or 100W of the same model if you really need the cutting power—either way it's a good base and may just need a little love to be perfect.

Reason being:

– You get the traditional auto focus where the bed moves and the head isn't variable.

– Your material height when doing batches would be constant.

– The head isn't retracting on job stop or completion.

It just makes for a better workflow for most people, and there's less hoops to jump through or remember prior to each time you hit start, and also less to break on a head with no moving parts. For Z depth, it's like WAY more capable. You can use pretty much any rotary and do just about any cup or round item as long as the rotary will hold it. The 60w a bigger machine, but it's only about 10 inches bigger in width and length. Height—I'm not sure if it matters for you—but I see that as a benefit anyway, and you get a stand so you can move it or level it if required. No tube extension like on the 100W version, so it's actually not awkwardly in the way either.

Also, pass-through—forgot to mention. You can do long sheets through the pass-through areas if you needed to. Makes long cut-outs of large single objects possible. Not a thing for everyone, but if it's in your wheelhouse, then it gets you in the door.

You will need to buy a separate chiller (make sure it's a real chiller and not just a pump + radiator), but honestly if you can swing the $400–$500 for it, it's just a way more capable machine and you'll get way more time and use out of it, way less limiting, and you'll be able to accept more jobs if you're doing job-shop work. This model base is also just a really good value. You get auto focus and a reasonable size, depth, speed, and it comes in at about 50% or more off the more premium options that come in a similar size. There are cheaper options at this size on eBay, but you REALLY sacrifice a lot of value and quality, so I think it's kinda the sweet spot for performance per dollar at the moment if you're okay with some tuning and polishing.

Job Shop vs Product Seller

Local business options is an awesome expansion route if you have feet in doors, so to speak. If job-shop is the goal, then versatility and flexibility is the idea—giving you max range in variety for doing as many materials as possible. If so, then a 30–60W fiber and the 60W 20x28 CO2 is probably how I would start as well. If you know you have a market or jobs lined up specifically require one over the other, then even if you start with one machine that fits all the needs and expand after the first few jobs, that's not a bad way to go either.

If you want the product route (if that fits your prospects in your area and could maybe do online sales too), I would plan out products/materials (not necessarily designs, but what exactly the materials you want to work with and sizes, etc.), and you can plan out what machines have more upfront value. You can still do job-shop stuff too on the side for extra income as you discover which products sell well – just another way to approach it and worth discussing to add into your expansion and build-out plans.

CO2 Galvo Considerations

As a little add-on consideration: if you don't plan on needing to cut literally anything—if you are doing cutting boards, powder-coated tumblers, Yeti, Stanley, whatever – another option for organics instead of a CO2 gantry is a CO2 galvo (parted out properly). It's faster, but it's NOT the right choice if you plan to cut. If you plan on making custom box cutouts or doing ornaments cutouts, or dinosaur bone assembly puzzles or whatever, get a gantry. Don't try to mix cutting materials with galvo starting out, it is a headache and not a great quality option in most cases. But if you needed to do like 100 tumblers on your day off from your normal 9–5 job, the CO2 galvo can make that happen in an afternoon—and a gantry is gonna be like 30–50% slower probably. It's been a while since I've looked at pricing, but it's a consideration option.

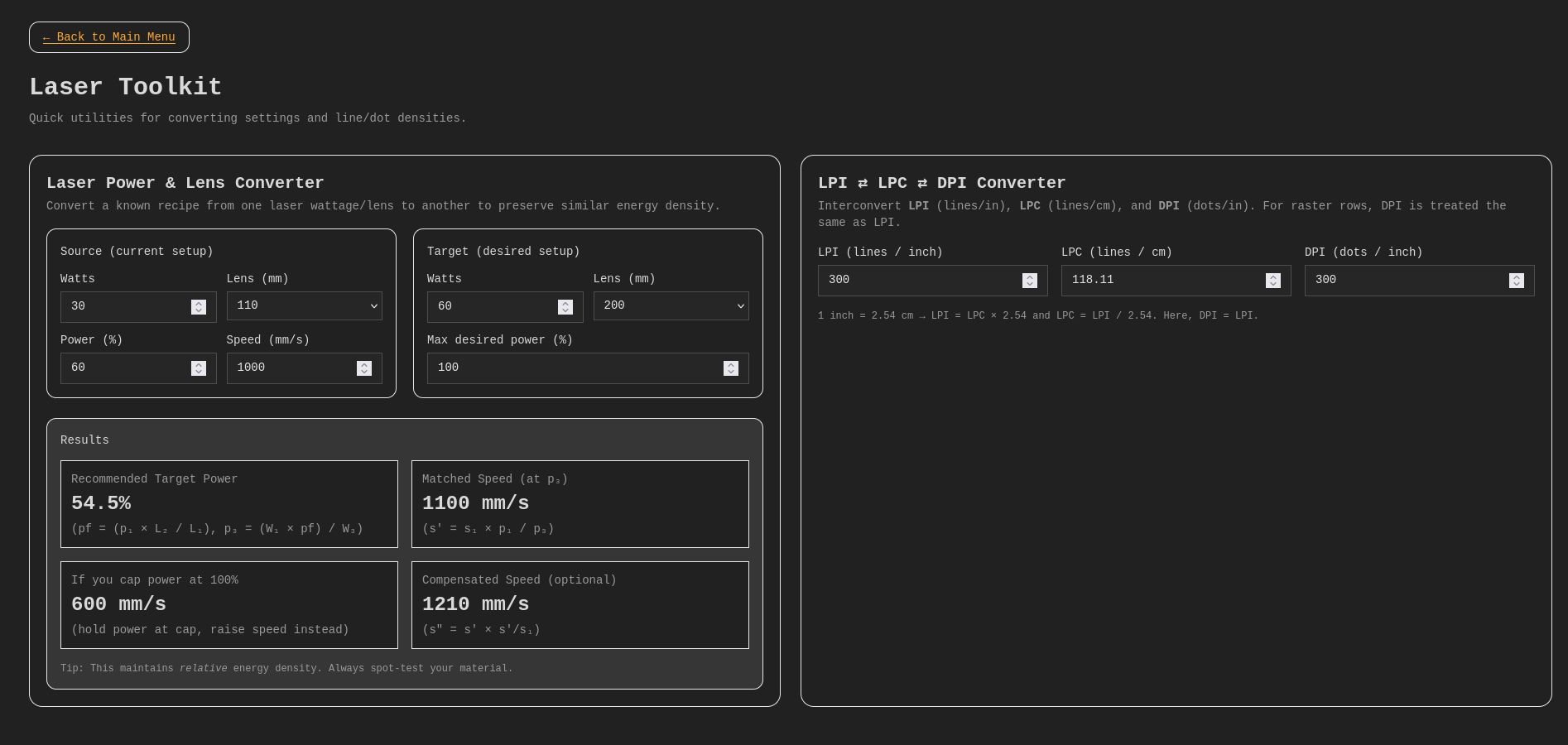

Fiber

For fiber, 20W can work, but if you need anything larger than 110mm on lens size to fit a project, there's a solid chance you may have some troubles. If you expand to a 200 lens, it really shows the lack of wattage quickly. If you can, I'd try and swing a 30W just in case. If you ever needed to use a 200 lens, or a 300 for coating removal, it would be much more in the ballpark for you and you won't feel quite as limited down the road.

For the cost difference between a 30W and 50 or 60W though, it might be worth considering the 60W, but it all depends on what you need and want to cover. If there is zero chance of needing to do copper marking or deep engraving, 30W may be plenty. Price differences for a non-MOPA are pretty appealing, but a MOPA 30W to 60W is really only like $800 difference or so I think, depending on what and where you get and the bundle of options included.

I absolutely love my 60W fiber. I could have gotten away with less power for most jobs, but with the extra power I can move through some jobs a little faster. Quick marking jobs are NOT where the extra wattage helps. It's the deep engraving stuff where it hits its stride—but you have to tune for jobs like that or it's just moving at the same pace. Some projects can function as a loss-leader for your time to get people in the door and your name out there though. Coins and stuff like that can be profitable if you're min-maxing your output and keeping your run time in consideration when doing design work.

Outside of that, 30 or 50W for basic marking is totally fine—it all depends on your planned or potential projects. The MOPA aspect of it with the M7 sources comes in with a little more reliability, gives you more tunable power delivery for really light plastic marking or really hardcore deep engraving and material removal.

A Note on Safety

No matter where you set up shop, your main priority should be your exhaust and air replacement.

It’s going to be expensive if you need a fume extractor, so cost-wise it would be best to plan for a 6” or 8” exhaust fan at your exit point with ducting to the machines so it sucks out (instead of blowing from far away) to outside where it’s not going to be pumped right into someone’s face or another window. Make sure you have an air inlet to replace the air you’re trying to suck out with the exhaust, even if you crack a window elsewhere. Air will find its way back in through suction, and you ideally want to make sure it’s clean air from nowhere near your exhaust. I get replacement air on the wall at the opposite side of my shop that I blow my exhaust out. A good air seal for the exhaust point is important too so the contaminated air doesn’t blow right back in the window it’s being pushed out—path of least resistance.

We've chatted on the channel about exhaust setups on the podcast, and I’ll be covering that as part of my ground-up shop build-out at my house where I’m moving (videos coming, just life chaos), so hopefully that helps with more detail on that.

DO NOT put that off. Don’t run the lasers unless you have it set up. It’s not worth your or your family’s health and well-being to push that.

For space-savings, the all-in-one style fibers are nice, but they are a little harder to work on if you need to repair them, and sometimes they use slightly custom parts depending on what you get. For that reason, I kind of have a bias toward standard split style fiber lasers (box with controller and electronics separated from the laser base/head/tower). It also makes it easier if you ever needed or wanted a taller tower for large objects—it's easier to replace and swap out.

Buying and Links

I'll include a few affiliate links (they support our team and help cover the time we spend helping out by awarding us a small comission.) If you don’t want to use them or have something else in mind, it’s all good – they're just there if you like the suggestions and want to support us. Won’t cost you anything extra.

I was trying to find a 50W JPT LP-sourced fiber as a slightly lower-cost option, but honestly there don’t seem to be any on Amazon that are worth linking – they are too close in price or more than the 60W options from reputable brands.

There are 50W Raycus options from Cloudray for a reasonable price, but I’m holding off on recommending that (Raycus issues, not Cloudray issues). Too long to explain without making this a longer novel, but you’ll see a video come out about it later.

It’s not worth the ~$2k in savings if your laser is going to be down for 2–3 months after you buy it, and have it sit in pieces after you fully disassemble it during that time for Raycus to have a 50% chance of fixing it on the first try.

In terms of purchasing both the 20x28 OMTech CO2 and any of the fibers, they all pretty much take up the same space regardless of how you mix nad match them. Minor difference for the AIO option if you are super strapped on space. Wattage on the fiber isn’t going to change much, or at all really on space, just weight.

I think no matter what options you pick in and around that range, you should be able to stay under that $10K mark and have some wiggle room to cover state taxes, extras, etc. you run into as you set up and find things you need—exhaust and all that.

Honestly, a really solid build-out and capability list.

If you’re looking for some other options, just let me know and I’ll be happy to help if I can.

Hope that helps!

Kind regards,

Kyle + The LE Team

This article contains affiliate links. When you make purchases using these links we get a small cut at no cost to you. These funds help us keep our site, channel and resources online for you and people like you.